Hayabusa Transmission for Cars: A Powerful Upgrade

The Suzuki Hayabusa, a motorcycle legend, is renowned for its incredible speed and powerful engine. But what if you could harness that power and integrate it into a car? Using a Hayabusa transmission in a car build, although complex, offers a unique and exciting way to achieve extreme performance. This article delves into the reasons, challenges, and possibilities of adapting a Hayabusa transmission for automotive applications, providing a comprehensive overview for enthusiasts and builders.

Why Choose a Hayabusa Transmission for Your Car?

Several factors contribute to the appeal of using a Hayabusa transmission in a car project. These include:

- Compact Size and Lightweight: Hayabusa transmissions are significantly smaller and lighter than traditional car transmissions, beneficial for weight reduction and space constraints, especially in smaller vehicles.

- Sequential Shifting: They offer the rapid-fire precision of sequential shifting, providing a race-car-like driving experience.

- High Revving Capability: Designed to handle the Hayabusa engine’s high RPMs, these transmissions are robust and capable of withstanding significant power output.

- Cost-Effective Performance: Compared to some high-performance aftermarket car transmissions, a used Hayabusa transmission can be a more budget-friendly option.

Challenges of Adapting a Hayabusa Transmission

While the benefits are enticing, adapting a motorcycle transmission for a car is not without its challenges:

- Custom Fabrication: Adapting the transmission requires extensive custom fabrication, including a bellhousing adapter to mate it to the engine, a custom driveshaft, and potentially modifications to the chassis.

- Gear Ratio Considerations: The Hayabusa’s gear ratios are designed for a motorcycle’s weight and aerodynamics. Recalibrating these ratios for a car may be necessary, potentially requiring custom gears.

- Reverse Gear: Most Hayabusa transmissions lack a reverse gear, necessitating the integration of an external reverse gearbox or a creative solution to achieve reverse functionality.

- Clutch and Shifting Mechanism: Adapting the clutch and shifting mechanism to car-like controls requires careful planning and execution.

- Durability Concerns: While strong for a motorcycle, the transmission’s long-term durability in a heavier car application needs to be considered, especially with increased power.

Key Considerations and Steps

Successfully integrating a Hayabusa transmission into a car involves careful planning and execution. Here are some key steps:

| Step | Description | Considerations |

|---|---|---|

| 1. Project Assessment | Evaluate the car’s weight, intended use, and engine power output. | Determine if a Hayabusa transmission is suitable for the application. Assess potential stress on the transmission. |

| 2. Transmission Selection | Choose a Hayabusa transmission in good condition, preferably with complete documentation. | Inspect the transmission for wear and tear. Consider the year and model for compatibility. |

| 3. Adapter Fabrication | Design and fabricate a custom bellhousing adapter to mate the transmission to the engine. | Ensure precise alignment to prevent vibration and premature wear. |

| 4. Drivetrain Modification | Modify or fabricate a custom driveshaft to connect the transmission to the rear axle. | Consider the length, diameter, and material of the driveshaft for optimal performance and durability. |

| 5. Shifting and Clutch Integration | Adapt the shifting mechanism to car-like controls (e.g., a shifter lever). Integrate the clutch system. | Ensure smooth and precise shifting. Consider using hydraulic clutches for easier actuation. |

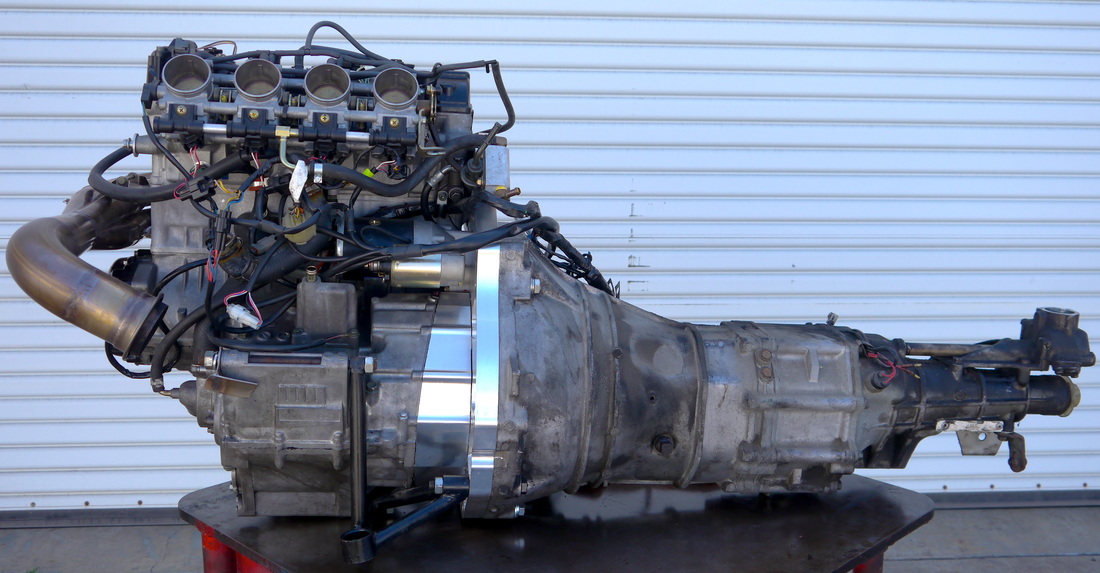

Example: Mating to different engines

Various engines can be adapted to work with a Hayabusa transmission. Common choices include other motorcycle engines (inline-4s are a popular choice) or even small, lightweight car engines. The key is the adapter plate, which must be precisely machined.

FAQ: Hayabusa Transmission in Cars Q: Is it legal to install a Hayabusa transmission in a car?

A: Legality depends on local regulations. Check with your local authorities regarding vehicle modifications and emissions standards.

Q: How much does it cost to install a Hayabusa transmission in a car?

A: Costs vary greatly depending on the complexity of the project, the cost of custom fabrication, and the price of the transmission. Expect to spend a significant amount of money.

Q: Can a Hayabusa transmission handle a lot of power?

A: While robust for a motorcycle, the transmission’s power handling capacity in a car application should be carefully considered. Overpowering the transmission can lead to premature failure. Modifications to the transmission internals can increase its durability, but this adds to the cost and complexity.

Q: Is it difficult to drive a car with a sequential transmission?

A: Sequential transmissions require a different driving style than traditional manual transmissions. They offer faster shifting but lack the forgiving nature of a conventional H-pattern gearbox. Practice is essential to master smooth and efficient driving.

Adapting a Hayabusa transmission for car use is a challenging but rewarding endeavor. It offers a unique combination of lightweight design, sequential shifting, and high-revving performance. However, it requires careful planning, custom fabrication skills, and a thorough understanding of mechanical principles. The end result can be a truly unique and exhilarating driving experience. If you’re considering this project, be prepared for a significant investment of time, money, and effort. Remember to prioritize safety and consult with experienced professionals for guidance and assistance. Ultimately, a well-executed Hayabusa transmission swap can transform a car into a performance machine unlike any other.

Hayabusa Transmission for Cars: A Powerful Upgrade

The Suzuki Hayabusa, a motorcycle legend, is renowned for its incredible speed and powerful engine. But what if you could harness that power and integrate it into a car? Using a Hayabusa transmission in a car build, although complex, offers a unique and exciting way to achieve extreme performance. This article delves into the reasons, challenges, and possibilities of adapting a Hayabusa transmission for automotive applications, providing a comprehensive overview for enthusiasts and builders.

Several factors contribute to the appeal of using a Hayabusa transmission in a car project. These include:

- Compact Size and Lightweight: Hayabusa transmissions are significantly smaller and lighter than traditional car transmissions, beneficial for weight reduction and space constraints, especially in smaller vehicles.

- Sequential Shifting: They offer the rapid-fire precision of sequential shifting, providing a race-car-like driving experience.

- High Revving Capability: Designed to handle the Hayabusa engine’s high RPMs, these transmissions are robust and capable of withstanding significant power output.

- Cost-Effective Performance: Compared to some high-performance aftermarket car transmissions, a used Hayabusa transmission can be a more budget-friendly option.

While the benefits are enticing, adapting a motorcycle transmission for a car is not without its challenges:

- Custom Fabrication: Adapting the transmission requires extensive custom fabrication, including a bellhousing adapter to mate it to the engine, a custom driveshaft, and potentially modifications to the chassis.

- Gear Ratio Considerations: The Hayabusa’s gear ratios are designed for a motorcycle’s weight and aerodynamics. Recalibrating these ratios for a car may be necessary, potentially requiring custom gears.

- Reverse Gear: Most Hayabusa transmissions lack a reverse gear, necessitating the integration of an external reverse gearbox or a creative solution to achieve reverse functionality.

- Clutch and Shifting Mechanism: Adapting the clutch and shifting mechanism to car-like controls requires careful planning and execution.

- Durability Concerns: While strong for a motorcycle, the transmission’s long-term durability in a heavier car application needs to be considered, especially with increased power.

Successfully integrating a Hayabusa transmission into a car involves careful planning and execution. Here are some key steps:

| Step | Description | Considerations |

|---|---|---|

| 1. Project Assessment | Evaluate the car’s weight, intended use, and engine power output. | Determine if a Hayabusa transmission is suitable for the application. Assess potential stress on the transmission. |

| 2. Transmission Selection | Choose a Hayabusa transmission in good condition, preferably with complete documentation. | Inspect the transmission for wear and tear. Consider the year and model for compatibility. |

| 3. Adapter Fabrication | Design and fabricate a custom bellhousing adapter to mate the transmission to the engine. | Ensure precise alignment to prevent vibration and premature wear. |

| 4. Drivetrain Modification | Modify or fabricate a custom driveshaft to connect the transmission to the rear axle. | Consider the length, diameter, and material of the driveshaft for optimal performance and durability. |

| 5. Shifting and Clutch Integration | Adapt the shifting mechanism to car-like controls (e.g., a shifter lever). Integrate the clutch system. | Ensure smooth and precise shifting. Consider using hydraulic clutches for easier actuation. |

Various engines can be adapted to work with a Hayabusa transmission. Common choices include other motorcycle engines (inline-4s are a popular choice) or even small, lightweight car engines. The key is the adapter plate, which must be precisely machined.

A: Legality depends on local regulations. Check with your local authorities regarding vehicle modifications and emissions standards.

A: Costs vary greatly depending on the complexity of the project, the cost of custom fabrication, and the price of the transmission. Expect to spend a significant amount of money.

A: While robust for a motorcycle, the transmission’s power handling capacity in a car application should be carefully considered. Overpowering the transmission can lead to premature failure. Modifications to the transmission internals can increase its durability, but this adds to the cost and complexity.

A: Sequential transmissions require a different driving style than traditional manual transmissions. They offer faster shifting but lack the forgiving nature of a conventional H-pattern gearbox. Practice is essential to master smooth and efficient driving.

Adapting a Hayabusa transmission for car use is a challenging but rewarding endeavor. It offers a unique combination of lightweight design, sequential shifting, and high-revving performance. However, it requires careful planning, custom fabrication skills, and a thorough understanding of mechanical principles. The end result can be a truly unique and exhilarating driving experience. If you’re considering this project, be prepared for a significant investment of time, money, and effort. Remember to prioritize safety and consult with experienced professionals for guidance and assistance. Ultimately, a well-executed Hayabusa transmission swap can transform a car into a performance machine unlike any other.