Embarking on the ambitious project of building a mid-engine car is a testament to engineering passion and a desire to push the boundaries of automotive design. This endeavor, far from being a simple bolt-together process, requires a deep understanding of vehicle dynamics, fabrication techniques, and a healthy dose of problem-solving skills. The allure of a mid-engine configuration lies in its potential for superior handling and weight distribution, offering a driving experience that is both exhilarating and precise. Successfully building a mid-engine car demands meticulous planning, careful execution, and a willingness to learn from both successes and setbacks.

Understanding the Mid-Engine Advantage

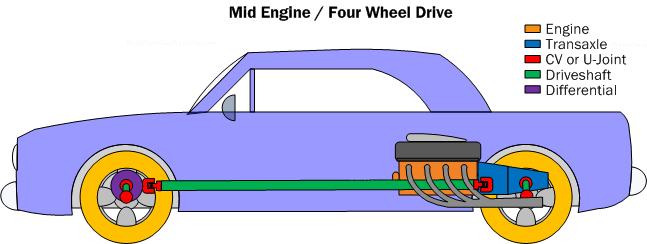

The mid-engine layout, where the engine is positioned between the driver and the rear axle, offers several key advantages:

Improved Weight Distribution: Placing the engine closer to the center of the car reduces polar moment of inertia, leading to quicker turning and more responsive handling.

Enhanced Traction: With the engine’s weight over the rear wheels, traction is significantly improved, especially during acceleration.

Optimized Aerodynamics: The mid-engine configuration allows for a more streamlined design, reducing drag and improving aerodynamic efficiency.

The Building Process: A Step-by-Step Guide

Building a mid-engine car is a complex undertaking, but breaking it down into manageable steps can make the process less daunting:

1. Planning and Design: This is the most crucial stage. Determine the car’s intended use (track, street, etc.), budget, and desired performance characteristics. Create detailed blueprints or CAD models.

2. Chassis Fabrication: Choose a suitable chassis design (space frame, monocoque, etc.) and begin fabrication. This may involve welding, cutting, and shaping metal.

3. Engine and Transmission Selection: Select an engine and transmission that meet your performance goals and budget. Ensure compatibility with the chosen chassis.

4. Suspension and Brakes: Design and install a suspension system that provides the desired handling characteristics. Choose brakes that are appropriate for the car’s weight and performance.

5. Bodywork: Fabricate or purchase body panels that fit the chassis and provide the desired aesthetic.

6. Wiring and Electronics: Install the wiring harness, ECU, and other electronic components.

7. Interior: Install seats, dashboard, and other interior components.

8. Testing and Tuning: Thoroughly test the car and make necessary adjustments to the suspension, engine, and other systems;

Challenges and Considerations

Building a mid-engine car presents several unique challenges:

Complexity: The mid-engine layout can be more complex to design and build than a front-engine or rear-engine configuration.

Cost: The cost of building a mid-engine car can be significant, especially if using high-performance components.

Space Constraints: Packaging the engine, transmission, and other components in the limited space of a mid-engine car can be challenging.

Cooling: Ensuring adequate cooling for the engine and other components can be difficult due to the limited airflow in the mid-engine compartment.

Choosing the Right Engine

Selecting the right engine is paramount. Consider factors like horsepower, torque, reliability, and availability of parts. Popular choices include:

GM LS Series Engines: Powerful, reliable, and readily available.

Honda K-Series Engines: High-revving and relatively lightweight.

Ford EcoBoost Engines: Turbocharged and fuel-efficient.

FAQ: Building a Mid-Engine Car

Here are some frequently asked questions about building a mid-engine car:

- Q: How much does it cost to build a mid-engine car?

- A: The cost can vary widely depending on the complexity of the project, the quality of the components, and the amount of labor involved. It can range from tens of thousands to hundreds of thousands of dollars.

- Q: How long does it take to build a mid-engine car?

- A: The time required can also vary widely, from several months to several years.

- Q: Do I need special tools or equipment?

- A: Yes, you will need a variety of tools and equipment, including welding equipment, metal fabrication tools, and diagnostic tools.

- Q: Is it legal to drive a home-built mid-engine car on the street?

- A: Regulations vary by state or country. You will need to ensure that the car meets all applicable safety and emissions standards.

The journey of building a car, especially one with a unique configuration, is a testament to human ingenuity and perseverance. The satisfaction of seeing your vision come to life, of feeling the raw power and precise handling of a machine you created, is unparalleled. With careful planning, diligent execution, and a passion for automotive engineering, you too can experience the thrill of building a mid-engine car.

Advanced Techniques and Considerations

Beyond the basic steps, several advanced techniques and considerations can elevate your mid-engine build:

- Computational Fluid Dynamics (CFD): Utilizing CFD software to optimize aerodynamic performance, ensuring efficient airflow around and through the vehicle. This can significantly impact downforce and drag.

- Finite Element Analysis (FEA): Employing FEA to analyze the structural integrity of the chassis and suspension components, identifying potential weak points and optimizing for strength and weight.

- Data Acquisition Systems (DAS): Integrating a DAS to monitor critical parameters like engine temperature, oil pressure, and G-forces during testing. This data can be used to fine-tune the car’s performance and identify potential issues.

- Custom Wiring Harness Design: Designing a custom wiring harness tailored to the specific needs of the car, minimizing weight and complexity while ensuring reliable electrical connections.

- 3D Printing for Prototyping and Manufacturing: Utilizing 3D printing to create prototypes of components, such as intake manifolds or aerodynamic elements, allowing for rapid iteration and refinement. In some cases, 3D printing can also be used to manufacture final parts.

The Importance of Suspension Geometry

The suspension geometry plays a crucial role in the handling characteristics of a mid-engine car. Careful consideration should be given to:

- Roll Center Height: Optimizing roll center height to minimize body roll and improve cornering stability.

- Camber Gain: Designing the suspension to provide appropriate camber gain during cornering, maximizing tire contact patch and grip.

- Toe Angle: Setting the toe angle to optimize steering response and stability.

- Anti-Squat and Anti-Dive: Adjusting anti-squat and anti-dive characteristics to control weight transfer during acceleration and braking.

Legal and Safety Considerations

Before embarking on this project, it’s crucial to understand the legal and safety implications:

- Vehicle Registration and Titling: Research the requirements for registering and titling a home-built vehicle in your jurisdiction. This may involve inspections and compliance with specific safety standards.

- Insurance: Obtain appropriate insurance coverage for the vehicle. This may require working with a specialty insurance provider.

- Safety Equipment: Install essential safety equipment, such as a roll cage, racing seats, and harnesses.

- Track Day Regulations: If you plan to track the car, familiarize yourself with the track’s safety regulations and requirements.

Resources and Community

Don’t underestimate the value of connecting with other builders and accessing available resources:

- Online Forums and Communities: Join online forums and communities dedicated to home-built cars and mid-engine conversions. These communities can provide valuable advice, support, and inspiration.

- Technical Books and Manuals: Consult technical books and manuals on chassis design, suspension geometry, and engine tuning.

- Local Car Clubs and Events: Attend local car clubs and events to network with other enthusiasts and learn from their experiences.

- Professional Consultants: Consider hiring a professional consultant with experience in automotive engineering and fabrication to provide guidance and expertise.

Ultimately, the success of your mid-engine car build hinges on meticulous planning, unwavering dedication, and a willingness to learn and adapt. Remember to prioritize safety, adhere to legal requirements, and leverage the wealth of knowledge available within the automotive community. The journey may be challenging, but the reward of driving a unique, high-performance machine that you built with your own hands is immeasurable. Building a mid-engine car is not just about creating a vehicle; it’s about pushing your limits and achieving something truly extraordinary.